Interfacing your smart connected world

Interfacing your smart connected world

Put simply we are the architect, the designer and the supplier of custom integrated electronic circuits embedded into our customers’ products for data collection, processing and data communication.

With 26 times more connected things than people (Gartner) and the emergence of artificial intelligence, we are now in an era of connected intelligence. In our connected world, almost all products use electronic functions, pushing innovations and creating new demands in the electronics supply chain.

Indeed, only smart electronics enables:

Here are the challenges we aim at contributing to.

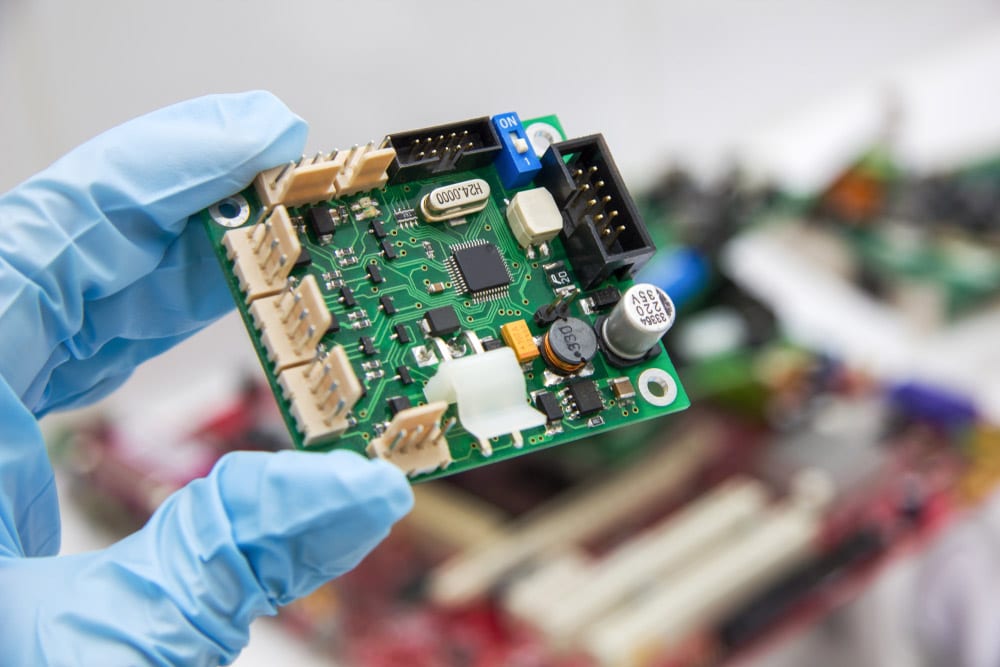

The electronics supply chain includes:

Located far upstream of the final electronic product market, semiconductors components, including custom Integrated Circuits (ASIC/SoC), are nonetheless widely recognized as a major driver for economic growth providing the indispensable technology for collecting, processing, storing and communicating information. Semiconductor components also offer effective ways to address the societal challenges of the 21st century, opening the door to machine learning, personalized healthcare, energy management, autonomous transportation, to name just a few applications.

Key semiconductors component, the custom Integrated Circuit is fundamental to address the demands for providing miniaturization, new functionalities, better performance, increased energy efficiency and improved safety and security of electronic subsystems.

At IC’Alps, we have the capacity to deliver first-time-right solutions from design, through industrialization to silicon manufacturing of ready-to-use custom Integrated Circuits. What’s more? In meeting the technical and societal challenges of our smart connected world, we are helping to accelerate the digital transformation.

1. Everything starts with our Sales and Marketing Team.

The Business Developers are responsible for promoting IC’Alps and identifying new potential customers that could benefits from ASIC integration in their products. During all pre-sales interactions with potential customers, our Business Developers are in first line. They work closely with our technology experts to help customers translate their ideas, needs and wants into a custom integrated circuit solving their problem. To support the sales team, our marketing department bears responsibility for raising brand awareness, generating qualified leads, planning advertising strategies, writing case studies and ensuring service differentiation from competitors.

ASIC production is composed of the following phases: ASIC design, ASIC layout, mask fabrication, wafer fabrication, wafer probing, package assembly, final testing, and shipping.

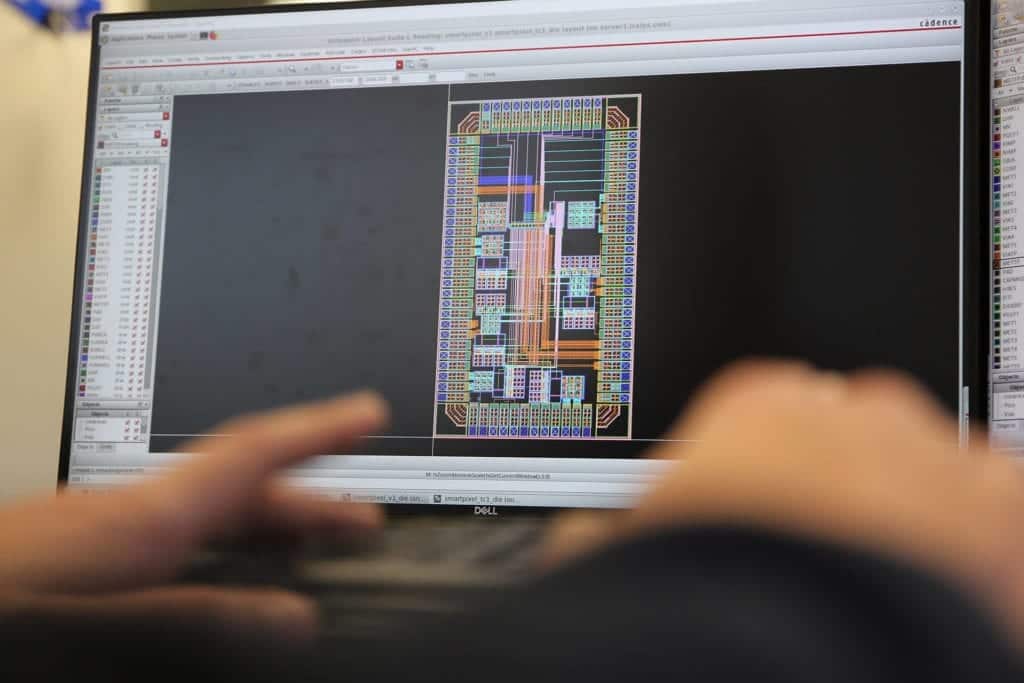

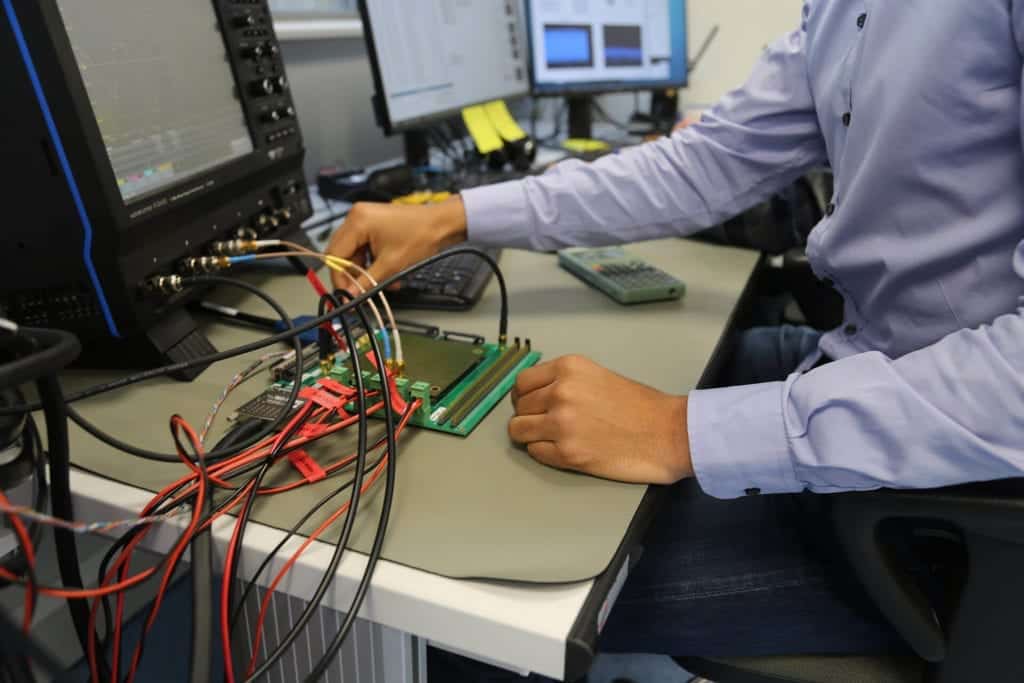

2. Once a customer comes on board, we set up a team of experts for ASIC implementation coordinated by a project manager. Our project manager is also the “voice of the customer” inside the company. Our ASIC architects will start by defining the drawings of the ASIC circuitry that might answer the customer needs. Then our logic and analog designers will design and verify the ASIC using specific Design Automation softwares to translate the drawings into transistors schematics and assemblies that fulfill the desired functions.

3. When it comes to ASIC prototyping and manufacturing, we call on our team dedicated to supply chain management. This team collaborates closely with key partners such as wafer manufacturers, packaging companies and test houses to achieve the best trade-off between time-to-market, production costs, and quality.

4. Outside these functions, we could not operate and grow without supporting functions such as HR, IT, Quality and Finance.