Immerse yourself in IC’Alps through the eyes of Gaëlle Dubus, Physical Implementation Engineer at IC’Alps, who shares her unique experience at the company.

My professional background

My name is Gaëlle Dubus, I’m 28 years old and I live in Montbonnot.

I began my studies with a preparatory course at INP Toulouse, which enabled me to enter the INP Phelma engineering school in Grenoble. There, I chose the Integrated Electronic Systems option.

I wanted to work in a concrete application field of physics. The choice of electronics was a natural one because of its ubiquitous presence in everyday objects.

I started my career working in the physical implementation flow, which is composed of multiple stages. I began working at the start of this flow (Synthesis, DFT, etc.) before moving on to place and route, and then sign-off. Now, I’m able to go througth the entire process.

Physical implementation is not something you typically learn in school, so I was trained from the beginning by more experienced colleagues who immediately placed their trust in me.

My job as Physical Implementation Engineer

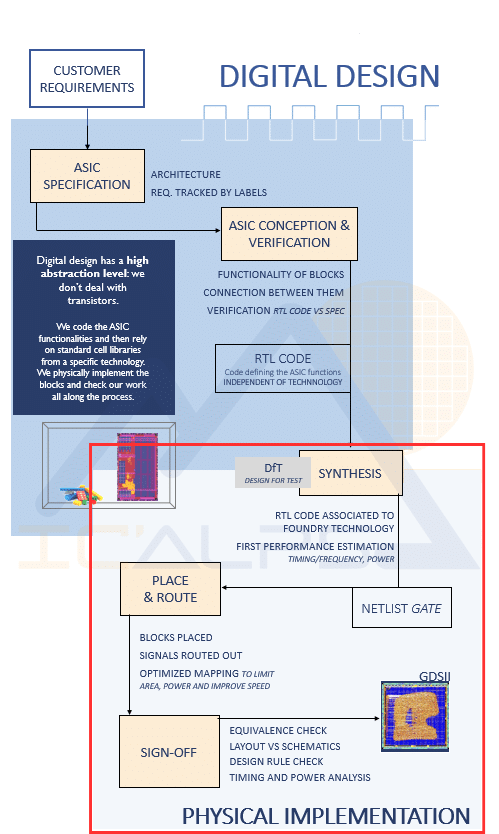

I’m a physical implementation engineer, responsible for executing all the steps involved in transforming the RTL code, which represents the circuit’s functionality (a step taken upstream by digital designers), into a GDS file that represents the drawing of the overall circuit and is used for mask design.

Most of the work is done using EDA tools, which allow us to carry out all stages of the implementation flow, from synthesis to the delivery of the GDSII (the circuit design sent to production). During projects, we have the opportunity to be in direct contact with customers and suppliers, and sometimes even work at their facilities.

To be more specific, my mission is to provide a GDS that accurately represents the original RTL. I work on both projects and feasibility studies, ensuring that we meet the customer’s requirements for performance, including power consumption, area, and frequency.

The main stages I work on are:

- Synthesis: This stage transforms the RTL into a netlist, translating the RTL into Boolean equations and then into an assembly of logic gates (mapped onto pre-existing standard cells). During synthesis, many optimizations are made, particularly for timing and power.

- DFT (Design for Test): This stage involves adding test elements (often in RTL) to verify that the circuit is free from manufacturing defects post-production. Modules are added to the circuit to check for defects, such as dust particles, helping to identify and eliminate faulty circuits.

- Place and Route: In this phase, the netlist is transformed into a GDS. The first step is creating the chip floorplan, including the I/O ring, IP placement, and power/ground net connections. Once the floorplan is ready, standard cells are placed, the clock tree is created, and all signals are routed.

- Sign-off: This involves all the checks before final delivery of the GDS, ensuring that design rules are met, the GDS functionality matches the initial RTL code, and the client’s timing and power performance requirements are fulfilled.

The main skills of a physical implementation engineer include analytical ability, a critical approach to problem-solving, and evaluating results. The job requires a proficiency in scripting and working with software (EDA tools), as well as strong communication skills for interacting with team members, clients, and suppliers. A good command of English is also essential, as it is used in many documents and with some customers.

Technically, familiarity with the physical implementation flow and mastery of its various stages come with experience.

For example, I worked on a chip test project for a client’s IP, a Non-Volatile Memory (NVM), which retains information even when the circuit is powered off. In this project, we had to adapt a technology initially designed for analog use to digital, which was a very interesting challenge. It was the first project where I managed the entire process, facing all the challenges of creating something new to meet expectations.

Learn more about our Custom IC Design Services

My experience at IC’Alps

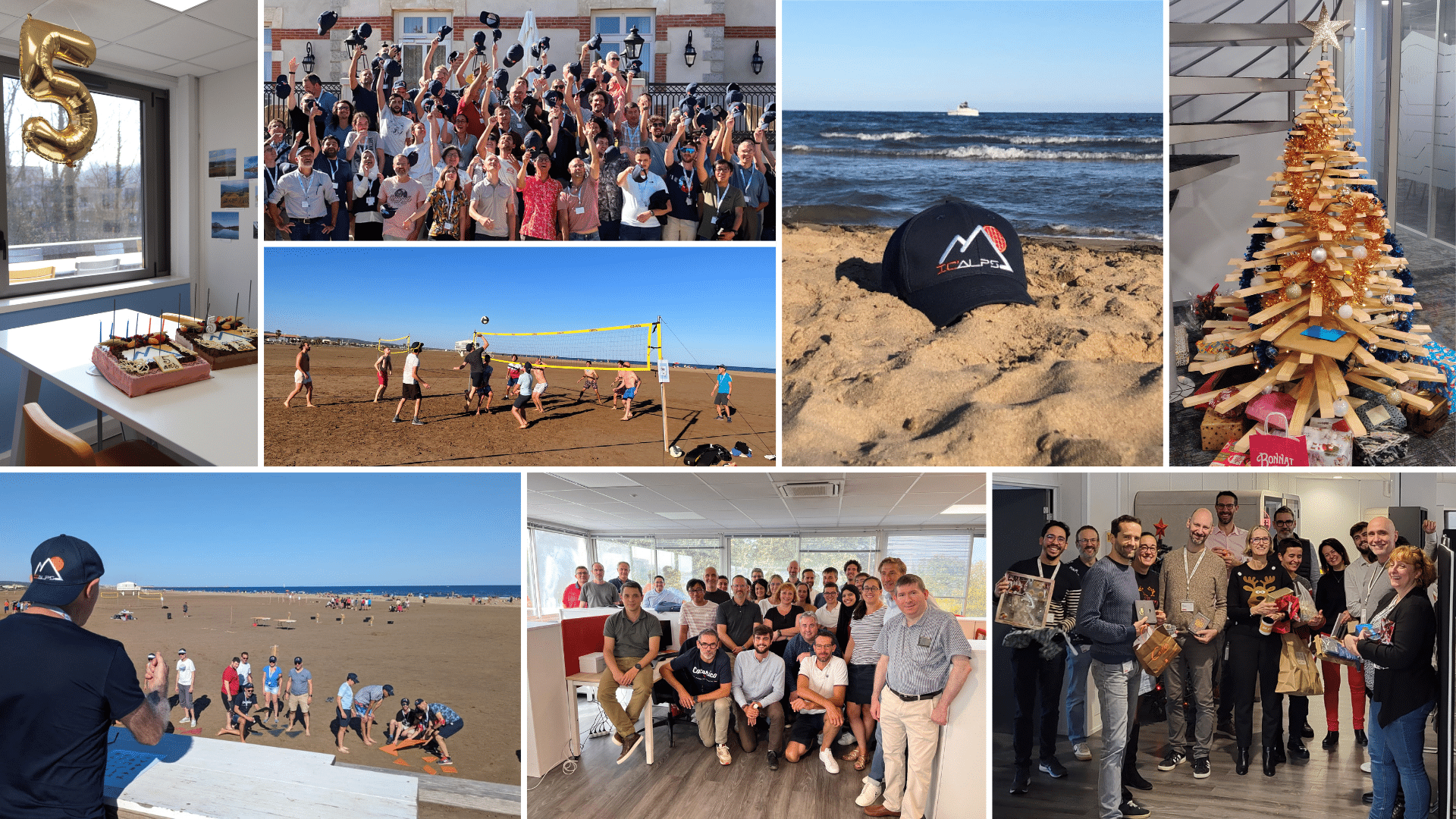

I joined the IC’Alps adventure right after my end-of-study internship, directly upon graduating from school.

I wanted to work in a small company where I could be versatile and develop multiple skills rather than being restricted to a single task in the integrated circuit development flow. I had already met the team and established some connections. IC’Alps, which had been recently created, expressed a desire to help train young people. So, I decided to join this project to contribute to its growth from the beginning, with a desire to feel useful and rise to the challenges of a young company.

IC’Alps is aware of its role in society, committed to training young people, and engaging in local actions such as sponsorship initiatives and collecting donations for charities.

The company pays particular attention to its quality processes and customer needs and expectations, ensuring quality delivery on time. We also have standards and certifications in the medical field and are working to obtain new ones in the automotive sector.

Another point that attracted me to IC’Alps was the opportunity to work in a small organization that fosters close relationships with colleagues and management, which is evident in the daily work atmosphere.

I am very committed to the company, serving as a member of the social and economic council. We hold regular meetings with the Board of Directors to discuss the life of the company, and I am involved in organizing company events. I also ensure that employees’ questions are answered to keep operations running smoothly.

I enjoy not being confined to one area of work and being surrounded by people with diverse experiences, both technically and culturally. It’s a rewarding place where you learn a lot.

Discover more about Analog Designer engineer

I quickly understood that IC’Alps pays particular attention to the development of young recruits by giving them real responsibilities and good prospects for development through diversity of its projects and its customers. I feel a real “team spirit” within this human-sized company. And, as an elected member of the CSE, I can say that the co-founders of the company are accessible and attentive to their employees. This is what makes IC’Alps so special!