Dive into the world of IC’Alps with Olivier Leman, Analog Designer, as he shares his inspiring journey and the innovative projects that define his experience at the company.

My professional background

I’m 43 years old and currently living in Grenoble. As a teenager I got to play around with an oscilloscope and discrete electronic devices my grandfather, himself fascinated with electronics, had in his garage. This is how I got in touch with integrated circuits and leant basics about bipolar and MOS technologies. I also played around with thermal and light sensor devices like thermistors and photoresistors, but got to understand that a basic transistor and an LED can operate as a temperature and a light sensor too, albeit with very different properties. My passion for electronics was born.

Later, after passing a Scientific Baccalauréat, I pursued a Diploma of general university studies in science and technology (DEUG) in Montpellier. After I join INSA Toulouse to complete my engineering studies, in Automation, Electronics, and Computer Science (AEI).

Then I began my career with a Ph.D. in Montpellier, focusing on the integration of ASICs and MEMS sensors. Over the years, I worked on innovative projects like a micro-accelerometer, through the years i learn mastering stat-of-the-art CAD tools and exploring hybrid designs that merged sensors and circuits into compact systems.

My professional journey also took me to Germany, where I spent eight years working in advanced research before returning to Grenoble in 2020. Joining IC’Alps shortly after the lockdown, as an analog designer with a certain interest linked to the medical field.

My job as Analog Designer

As an Analog Designer, my work revolves around designing and optimizing the analog components of integrated circuits. These components ensure that the final product meets the customers specifications while maintaining robust and reliable performance. My role covers all stages of the design cycle, from understanding customers needs to delivering a fully functional design.

how is my work organized ?

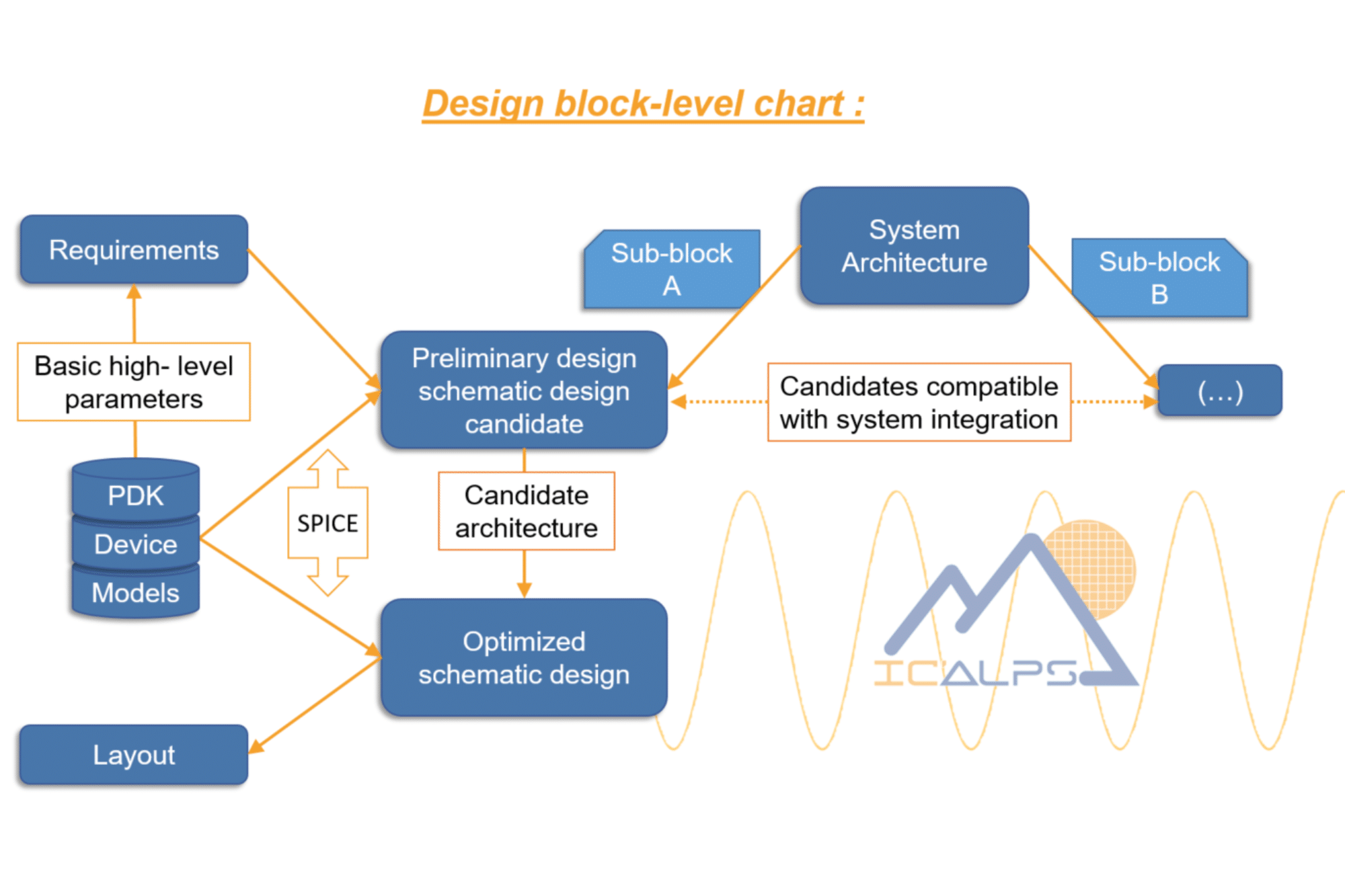

A typical project often starts with project planning and specification drafting. This involves working with customers to make sure we correctly understand their needs and break-down complicated functions into smaller, manageable blocks. For example, a filter might be decomposed into basic elements such as amplifiers and switches, each with specific design constraints. Often several candidate solutions are available which address a set of requirements, and the selection criteria might not be clear at first sight. Pre-design projet phase highlights which candidate solution is the best trade-of to meet the requirements. Once specifications are clear, I move on to the implementation optimization phase. Pre-design and design optimization phases make extensive use of CAD tools to study PDK devices, create schematics, simulate circuits and ensure their behavior matches with the requirements.

Throughout the process, I aim to create a robust design that can handle a variety of customers use cases. This means anticipating potential challenges, testing rigorously, and incorporating safety margins to ensure stability and reliability under all operating conditions.

Key Responsibilities

My work can be compared to assembling Matryoshka dolls: each block must seamlessly fit with others to create a cohesive system. And to do this we have a set of responsibilities that includes:

- Decomposing complex functions into smaller, testable blocks.

- Implementing designs using selected PDK (Process Design Kit) components to minimize the ASIC manufacturing maskset what shrinks the NRE (Non Return Engineering costs) while meeting requirements.

- Anticipating and mitigating risks by conducting risk analyses and executing extensive verifications including robustness checks like running Safe-Operating Area verifications.

- Collaborating with customers to refine specifications and ensure alignment of our work with their needs.

Skills and Expertise :

Being an Analog Designer requires technical rigor, organization, and a critical mindset. The design work starts by indentifying sizing parameters and writing sizing calculations. Experience teaches humility, starting each new design with a fresh perspective ensures no bias in decision-making. Anticipating how components interact and adapting designs based on their properties are key aspects of the job.

A Memorable Project i worked on :

One of the standout projects I’ve worked on was a current sensor for automotive applications. This sensor uses TMR (Tunnel Magneto-Resistive) technology to measure magnetic fields . I was involved in the design of various blocks including a feature-rich output amplifier, which required a deep understanding of the interfaces between the ASIC and the external environment.

Placed near to a cable, the sensor measures the current flowing through it what finds applications like monitoring the state of charge of a battery. This project exemplifies how analog design combines technical precision with innovative problem-solving to deliver impactful solutions.

Learn more about our Custom IC Design Services

My experience at IC’Alps

What makes IC’Alps unique ?

At IC’Alps, the focus on employee socialization stands out. Regular social events help create a strong sense of community, where everyone knows each other. As a small company, it fosters simplified and pleasant relationships, with a flat hierarchy that makes collaboration easy and enjoyable.

I was drawn to IC’Alps because of its focus on biomedical projects. Working on products with real added value, especially in the medical field, is incredibly rewarding. Each project is unique, offering constant opportunities for exploration and discovery, I’ve never worked on the same thing twice! It requires a lot of work but it’s very enjoyable.

The diversity of projects is another key factor. We’re exposed to a wide range of challenges, which allows us to propose innovative solutions and truly make a difference.

Thanks to collaborations within our group that provide privileged insights, at IC’Alps, we have the chance to work on cutting-edge technologies. This enables us to design optimized ASICs with advanced and ethical R&D, especially in fields like ultrasonic imaging, this is a specialty that few companies can match.

The company also places importance on CSR (RSE). On a personal level, I come to work by bike, we all contribute a little to the environment.

The company’s with an human size, combined with its ambitious projects, makes it a truly special place to work.

Discover more about physical Implementation Engineer